3D printers are remarkable devices that produce actual items from computer-generated pictures. To do this, tiny sheets of plastic, metal, and other materials are meticulously layered on top of one another until the final product is created. You might think of them as highly developed craft machines that can create a wide range of items, including toys, tools, specific components, and even works of art. With the use of this cutting-edge technology, we are redefining how we create things and realizing our digital concepts.

2D and 3D printer: What’s the difference

Documents, images, and vibrant posters may all be printed using 2D printers, like the ones you probably have at home or the workplace. They produce flat images or text that you can read and share by depositing ink or toner on flat sheets of paper. In the contemporary day, 3D printers from 3D printer heater vendors are comparable to magical craftspeople. They create three-dimensional items from your ideas, rather than merely printing flat photographs, to make your ideas come to life. It appears as though they are sculptors using a computer as a template. They build up layers of materials like plastic or metal until they have created a tangible, touchable object. This gives up a wide range of opportunities, including creating unique toys and spare parts as well as detailed sculptures and working prototypes for new technologies. In summary, 2D printers are used to create flat images, but 3D printers act more like 3D sculptors and create tangible objects that can be handled and used.

How 3D printers work

3D printers work by creating three-dimensional objects layer by layer. Here’s a simplified explanation of how they operate:

Design: The process begins with a 3D digital model of the object you want to create. This model is typically designed using computer-aided design (CAD) software or obtained from a 3D scan of an existing object.

Slicing:

The 3D model is then processed by slicing software, which divides it into very thin horizontal layers, like slicing a loaf of bread. Each layer represents a cross-section of the object.

Printing:

The 3D printer uses this sliced information as instructions. It starts at the bottom layer and works its way up. Here’s a step-by-step breakdown of the printing process:

Material Deposition:

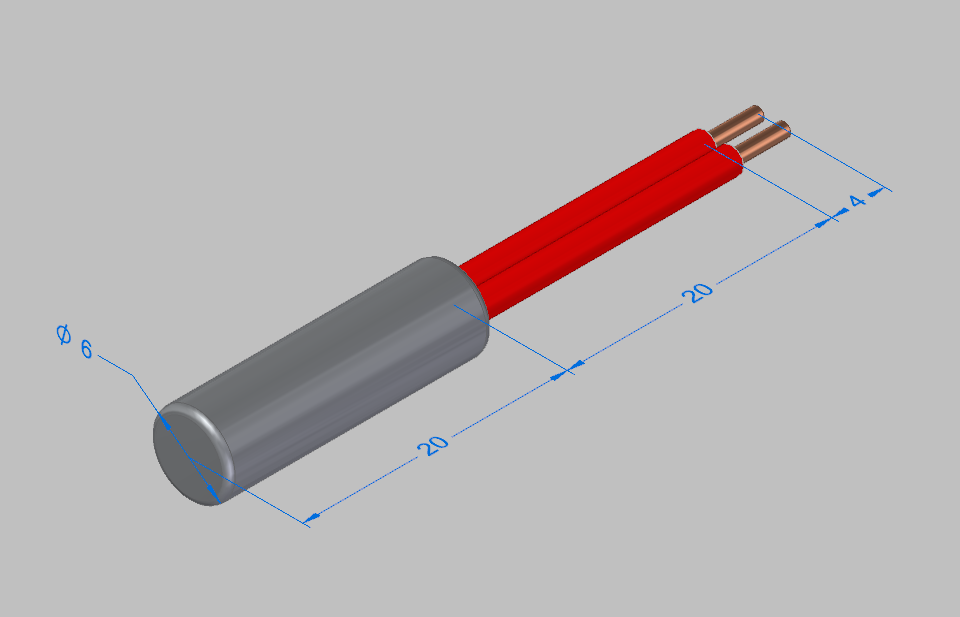

The 3D printer heats up the chosen material, typically plastic filament or resin, until it becomes molten (for Fused Deposition Modeling or FDM printers) or cures it using UV light (for Stereolithography or SLA printers). This material is then precisely deposited onto the build platform or the previous layer.

Layer by Layer:

The printer repeats this process for each layer, gradually building up the object. It follows the instructions from the slicing software, moving the print head or build platform in three dimensions (X, Y, and Z axes) to position the material accurately.

Cooling and Solidification:

As each layer is added, the material quickly cools and solidifies. This creates a bond between the layers, ensuring the object remains stable and coherent.

Completion:

Once all the layers have been printed and the object is complete, it may undergo post-processing steps such as removing support structures (if used), cleaning and surface finishing to improve its appearance and functionality.

Removal:

Carefully removing the final 3D-printed item from the construction platform. Additional stages may be necessary to complete the item depending on the 3D printing technology being used, such as UV light curing for resin-based printers. The ability to create a wide range of forms and intricate details is the secret of 3D printing’s adaptability. This makes it a useful tool in a variety of industries, including manufacturing, aircraft, and even the arts and sciences. Rapid prototyping, personalization, and the development of intricate geometries are all made possible. Using conventional production techniques, this would be difficult or impossible to do.

Future and Trends of 3D printers

According to the CO2 regulator manufacturer, the future of 3D printers is full of promise. These machines turn into even greater fame, with greater human beings and companies using them. They’ll get faster and use a wider range of substances, not just plastic and metal. You’ll see big things like motors and even entire buildings being made with three-D printers.

With the development of body parts and even personalized medicine therapies, 3D printers become incredibly useful as a treatment. Plus, they might produce less garbage, which would be better for the environment. You will be able to obtain products specifically made for you. And faculty students will research every aspect of their utilization. Therefore, 3-D printers are poised to transform how we produce goods in a variety of exciting ways.

The world is changing because of 3D printers.

3D printers are having a profound impact on the world. They enable individuals and organizations to design and communicate valuable products more accurately and successfully. This technological marvel accelerates the innovation of the latest products, thereby benefiting many industries in the medical field. Where personalized clinical equipment is created, to the entertainment sector where specific toys and collectibles are born. Additionally, 3D printers contribute greatly to sustainability by minimizing waste through disposable fabric use. They also have the potential to revolutionize space exploration because they can build the critical tools and systems needed in the harsh conditions of space. Essentially, 3D printers are like modern-day wizards, reshaping the way we create, innovate, and use gadgets in our regular lives and beyond. Their ability to turn digital ideas into tangible reality has opened up a world of opportunity and continues to shape the future in exciting ways.

Conclusion

In conclusion, 3d printer heating are changing the world by revolutionizing the way we create, innovate, and manufacture objects. They empower individuals and businesses to design and produce custom items quickly and affordably, spanning various industries from healthcare to entertainment. With their potential to reduce waste and contribute to space exploration, 3D printers are like modern-day sorcerers, reshaping our future.