Introduction:

In the intricate dance of modern industry, the seamless movement of materials is a key factor in ensuring efficiency and productivity. Among the unsung heroes of material handling systems are conveyor pulleys and conveyor belts. These seemingly simple components play a crucial role in the smooth transportation of goods in various industries. In this article, we will explore the significance of conveyor pulleys and conveyor belts, their types, and their indispensable role in the world of material handling.

Conveyor pulleys and conveyor belts play a vital role in material handling systems, serving as the indispensable components that keep operations moving smoothly. The conveyor pulley acts as the driving force behind the system, providing the necessary torque to move materials along the belt. Its design directly impacts the efficiency and reliability of the entire conveyor system. On the other hand, conveyor belts are not merely passive carriers but rather active participants in material transportation. They must be carefully selected based on factors such as material type, size, and durability requirements to ensure optimal performance. Together, these two elements form a dynamic duo that is essential for streamlining material handling processes across industries.

In addition to their functional importance, conveyor pulleys and belts also contribute significantly to workplace safety. Their proper maintenance can help prevent unexpected breakdowns or accidents that may result from faulty equipment. Furthermore, advancements in technology have led to innovative designs that enhance both efficiency and safety within material handling systems. As we continue to explore new materials and manufacturing techniques, we can anticipate even greater improvements in conveyor pulleys and belts that will revolutionize material handling practices for years to come.

The Basics of Conveyor Pulleys:

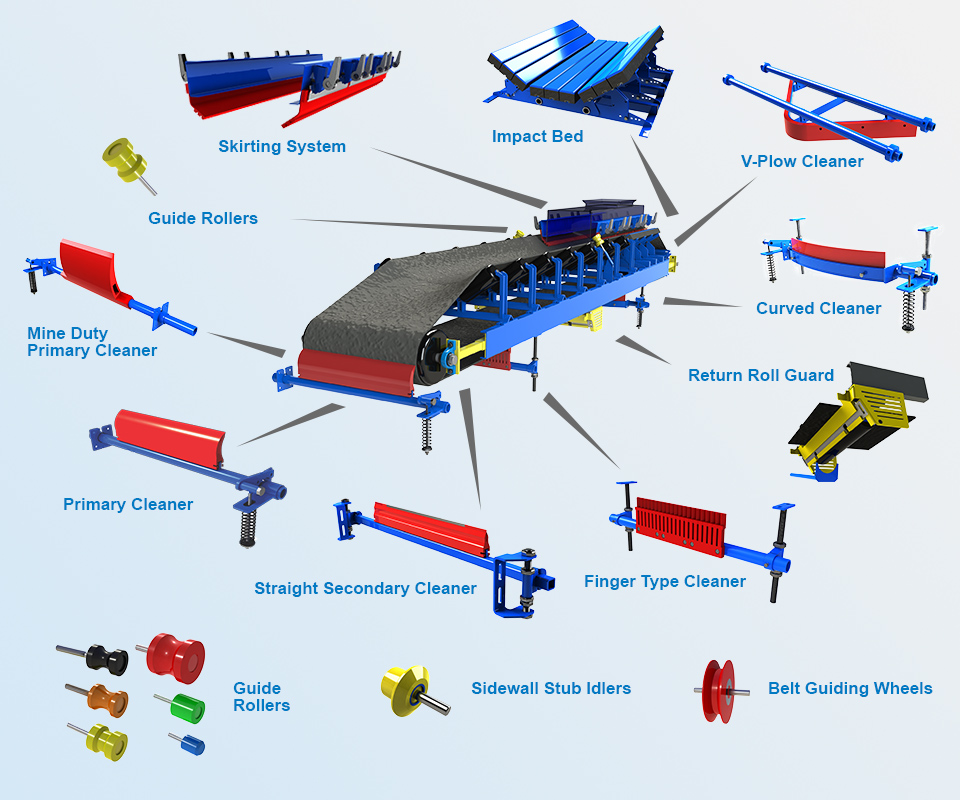

Conveyor pulleys are cylindrical devices that serve as key components in belt conveyor systems. They are strategically placed at both ends of the conveyor to support the conveyor belt and facilitate its movement. The primary function of a conveyor pulley is to redirect the belt, providing tension and guidance to ensure smooth and controlled transportation of materials.

Conveyor pulleys come in various types, each designed for specific applications. Drive pulleys, for instance, are connected to the motor and generate the motion needed to propel the conveyor belt. On the other hand, idler pulleys are non-powered pulleys that redirect and support the belt. The combination of these pulleys creates a synchronized system that efficiently moves materials from one point to another.

Materials used in the construction of conveyor pulleys are carefully selected to withstand the demanding conditions of industrial environments. Common materials include steel, which provides strength and durability, and rubber, which is often used for coating to enhance friction and protect the belt.

Understanding Conveyor Belts:

Conveyor belts are continuous loops of material that rotate around a series of pulleys, facilitating the movement of goods from one point to another. These belts are typically made of layers of rubber or fabric, which are combined to form a robust and flexible conveyor medium. The selection of belt material depends on the specific requirements of the application, considering factors such as load capacity, speed, and environmental conditions.

The Importance of Conveyor Belts in Material Handling:

Conveyor belts are the backbone of material handling systems, providing a reliable and efficient method for transporting goods within a facility. Whether in manufacturing plants, distribution centers, or airports, conveyor belts are ubiquitous, streamlining processes and significantly reducing manual labor.

The versatility of conveyor belts is evident in their ability to handle a wide range of materials, from small and lightweight items to heavy and bulky goods. This adaptability makes them an ideal solution for industries as diverse as mining, food processing, and automotive manufacturing.

Types of Conveyor Belts:

Conveyor belts come in various types, each designed to meet specific industrial needs. Some of the common types include:

-

Flat Belt Conveyors: These are the most commonly used conveyor belts and are suitable for transporting a wide variety of materials.

-

Cleated Belt Conveyors: Equipped with vertical cleats, these belts are designed to prevent materials from sliding backward.

-

Modular Belt Conveyors: These belts consist of individual modules linked together, providing a flexible and customizable solution for specific applications.

-

Steel Belt Conveyors: Ideal for heavy-duty applications, these belts are made of interlocking steel pieces and are capable of handling large loads.

The Symbiotic Relationship:

The synergy between conveyor pulleys and conveyor belts is crucial for the seamless operation of material handling systems. The drive pulley, often connected to an electric motor, imparts motion to the conveyor belt. As the belt moves, the idler pulleys redirect and support it, ensuring a continuous and controlled flow of materials. This symbiotic relationship is fundamental to the efficiency of conveyor systems, as any disruption in the coordination between pulleys and belts can lead to downtime and decreased productivity.

Maintenance and Optimization:

To ensure the longevity and efficiency of conveyor pulleys and belts, regular maintenance is essential. This includes monitoring for signs of wear, adjusting tension, and lubricating components as needed. Additionally, technological advancements have led to the development of smart conveyor systems that utilize sensors and automation to detect issues before they escalate, allowing for proactive maintenance.

Furthermore, optimizing the design of conveyor systems can enhance their performance and energy efficiency. Engineers are continually exploring ways to reduce friction, improve belt materials, and enhance the overall design of conveyor pulleys to create more sustainable and cost-effective solutions.

Conclusion:

In the grand symphony of modern industry, conveyor pulleys and conveyor belt play a foundational role, ensuring the smooth and efficient movement of materials. From the drive pulleys that power the system to the conveyor belts that carry the load, these components work in tandem to facilitate the intricate dance of production and distribution.

As industries continue to evolve, the demand for innovative and efficient material handling solutions will persist. Conveyor pulleys and belts, often overlooked but indispensable, will remain at the forefront of these advancements, driving the wheels of progress in manufacturing, logistics, and beyond.