An electric motor is an electrical machine that converts electric energy to mechanical force. Most motors achieve this via interactions between magnetic fields and conductors that carry direct (DC) or alternating current (AC). surplus motor are the best Motors These conductors are connected to a commutator, a rotating electrical switch which regularly reverses current flow in the rotor windings. Soft conductive brushes make contact with individual segments of the commutator as the motor rotates, providing smooth contact.

Parts

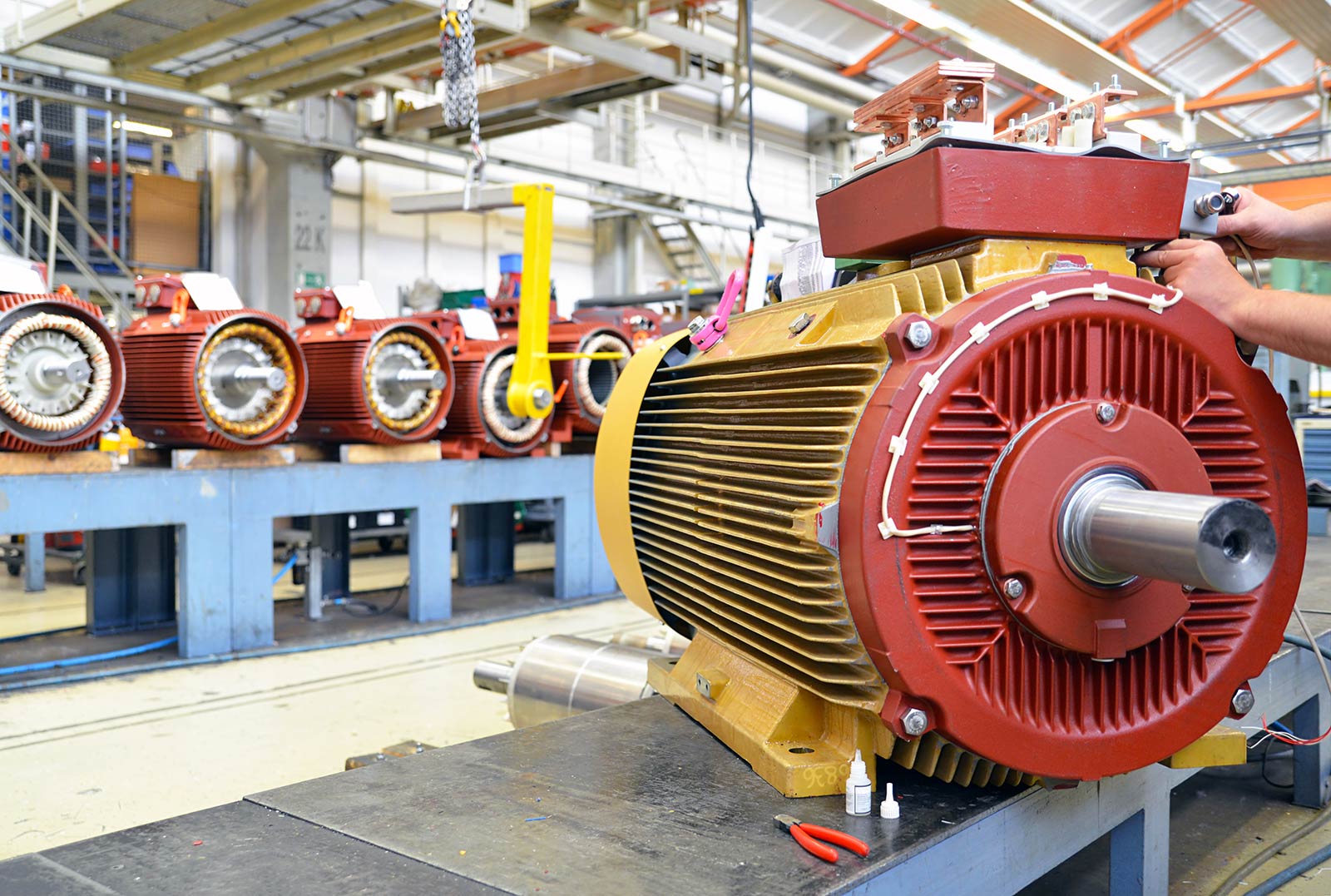

Electric motors are devices which convert electrical energy into mechanical energy that can be translated into rotational movement, such as turning. It may be powered either directly from batteries or rectifiers or indirectly via AC sources like power grids and generators. Electric motors consist of two key parts, the rotor and stator. The former contains conductors that carry current that interacts with magnetic fields in the latter to generate forces that turn the shaft.

The stator is a stationary outer shell comprised of steel alloy laminations wound with wire to create induction coils powered by three-phase AC power sources. A commutator, or rotating electric switch, periodically reverses current flow in rotor windings as shaft rotation occurs; electrical contacts made of soft conductive materials like carbon press against it to make contact between consecutive segments for current distribution to rotors.

How to buy an electrical motor

When choosing an electric motor, several factors should be taken into account, including voltage, current, speed, torque and power output. Additional concerns may include maintenance requirements, size/weight considerations and environmental compatibility.

Your application’s power requirement will dictate the size and type of motor necessary. Furthermore, take into account if food-grade motors are suitable, or whether moisture/water will come in contact with it. Other critical considerations in your application are speed and torque requirements. Speed refers to rotational speed; often measured in revolutions per minute (RPM); while torque measures how much force or twisting power a motor can generate.

As part of your motor selection, it is also necessary to consider how it will connect to other equipment and systems, to ensure proper fit, compatibility and communication standards compliance. Noise and vibration levels as well as environmental considerations like recyclability, energy efficiency compliance regulations and environmental responsibility should also be carefully taken into account when choosing a motor.

Electric motors for sale

Electric motors are commonly found in applications like blowers and pumps, industrial fans, machine tools, household appliances, disk drives and vehicles. Their operation involves the interaction between their magnetic field and electric current running through wire windings to produce torque on their shaft, while being powered either through direct current (DC) batteries or rectifiers or via AC from power grid or generators.

Electric motors contain many complex parts, so they must always be kept clean to avoid internal problems and properly lubricated at regular intervals to maintain peak performance levels. Too much lubrication could result in premature wear.

Used electric motors

Used industrial electric motors make for an excellent solution in several applications. At significantly lower costs than new units, used ones allow businesses to meet their goals without going over budget or being environmentally-friendly since producing mechanical devices requires lots of energy.

Nameplates of electrical motors display their output power (watts or kilowatts delivered to the shaft). This is measured as horsepower. A GE industrial electric motor’s maximum power output can also be found listed here.

GE industrial electric motors are reliable and durable products with advanced technology used for various applications across aerospace transportation, petrochemical processing, power generation and more. Their global network of field engineering services and repair facilities keeps industrial operations running smoothly while they have made several strategic acquisitions to further strengthen their position within their respective industries.

Surplus motors

Opting to purchase surplus electric motors has many advantages over buying brand-new ones, such as faster turnaround times and reduced costs, as well as being more eco-friendly since manufacturing new motors requires considerable energy consumption. buy electric motor from surplusrecord industrial electrical motors are the best buy of electric motor used electric motor for sale at surplusrecord.

Electric motors convert electrical energy to mechanical energy, propelling a shaft to rotate. Their operation depends on an interaction between magnetic field and current in wire windings that generate force applied on the shaft in the form of torque torque.

Motors can operate using either AC or DC current; most industrial motors prefer AC while DC motors may also find use. An used electric motors can range in size from that found in a mixer to those found on ships’ diesel engines; most utilize both rotor and stator assemblies; the former contains coil wires wrapped around an iron-ferromagnetic core that generates magnetic forces (Lorentz force) when activated with electricity; its separation from its stator counterpart by an air gap designed to ensure optimal performance.

Industrial electric motors

Industrial electric motors are one of the primary consumers of electricity worldwide. Optimizing efficiency in these motors and motor-driven systems can help decrease ownership costs while curbing growth of electricity demand.

An electric motor consists of two main parts, the stator and rotor. The former features metal bars connected by induction coils which create magnetic force to turn the shaft and produce mechanical output energy, while the latter contains steel alloy laminations with electrical current windings that interact with magnetic fields to generate torque.

Every motor requires lubrication in order to run at its optimal performance level, but not all lubricants are created equal. Knowing which lubricant best suited for each motor can extend its lifespan while decreasing maintenance expenses and maintenance expenses. A regular cleaning schedule also greatly extends lifespan and performance; in addition, the type of lubricant must fit the type of motor as well as operating conditions to prevent early wear-and-tear.