Introduction:

Mitsubishi Programmable Logic Controllers (PLCs) are an integral part of industrial automation and enable precise control and monitoring of machines and processes. This comprehensive guide aims to provide a thorough introduction to Mitsubishi PLCs Training Course, covering their history, key features, programming basics and applications.

Understanding PLC Mitsubishi

History and Evolution Mitsubishi Electric Corporation, a global leader in industrial automation, introduced its first PLC in 1978. Over the years, Mitsubishi PLCs have evolved significantly, incorporating advanced technologies and expanding their capabilities. Today, they are known for their reliability and versatility in various industries.

Key Features of Mitsubishi PLCs

Key Features of Mitsubishi PLCs Mitsubishi PLCs offer a wide range of features that make them suitable for a variety of applications:

High processing speed Mitsubishi PLCs are equipped with powerful processors that ensure fast execution of control tasks, making them ideal for real-time applications where accuracy is paramount.

Robust communication

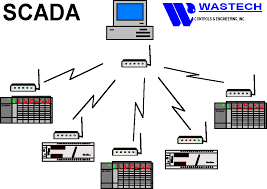

Robust communication These PLCs support multiple communication protocols, enabling seamless integration with other automation components and systems.

PLC I/O capabilities

Mitsubishi’s extensive PLC I/O capabilities come with a variety of input and output modules that allow users to customize their systems to meet specific requirements.

Mitsubishi PLC programming

Mitsubishi PLC programming capabilities are programmed using ladder logic, a graphical programming language that is intuitive for engineers and technicians.

Basics of PLC programming

Ladder Logic Ladder Logic is the basis of Mitsubishi PLC programming. It uses symbols and diagrams to represent logic functions, making it easier to understand and edit. Ladder diagrams consist of rungs that contain various instructions, including input conditions, output actions, and control functions.

Basic instructions PLC Mitsubishi offers a wide range of basic instructions such as AND, OR, NOT, timers, counters and comparators. These instructions are used to create complex control logic for industrial processes.

Development and debugging

Programming Tools Mitsubishi provides user-friendly programming software such as GX Works3 that simplifies the development and debugging of PLC programs. This software offers a rich feature set, including simulation tools and a user-friendly interface.

Data Handling Mitsubishi PLCs excel in data handling capabilities and enable users to efficiently manipulate and store data. This is necessary for data logging, recipe management and data analysis.

Application of Mitsubishi PLC

Manufacturing Industry Mitsubishi PLCs are widely used in manufacturing plants for process control, material handling and quality assurance. They ensure smooth operation and accuracy on production lines, resulting in improved product quality and reduced downtime.

Automotive sector

Automotive Industry in the automotive sector, Mitsubishi PLCs play a vital role in assembly lines, robotic welding and quality control systems. Their high-speed processing and reliability contribute to the efficiency and safety of automobile production.

Mitsubishi PLC food and beverage industries are essential to food and beverage production for tasks such as packaging, filling and sorting. They ensure consistent product quality and compliance with safety regulations.

Power Sector Mitsubishi PLCs

Power Sector Mitsubishi PLCs are used in power generation and distribution systems to monitor and control electrical equipment. Their advanced communication capabilities enable remote monitoring and preventive maintenance.

Advantages of PLC Mitsubishi

Reliability Mitsubishi PLCs are known for their robustness and long life, ensuring continuous operation in critical applications.

Mitsubishi’s PLC modular design

Scalability These PLCs offer scalability and allow users to expand their systems by adding additional modules or CPUs as needed.

Ease of Maintenance Mitsubishi’s PLC modular design simplifies maintenance and troubleshooting, reducing downtime and maintenance costs.

Global Support Mitsubishi Electric provides extensive customer support, including training, technical assistance, and availability of spare parts, ensuring the longevity of their PLC systems.

Conclusion:

Mitsubishi PLCs have a rich history and boast a wide range of features and capabilities that are suitable for various industries. Their ease of programming, reliability and scalability make them an ideal choice for industrial automation. Thanks to continuous advances in technology, Mitsubishi PLCs are poised to remain at the forefront of the automation industry and contribute to increased efficiency and precision in industrial processes worldwide.