In the fast-paced world of industrial processes, the ability to make repairs or modifications without shutting down entire systems is invaluable. This is where line stopping comes into play, revolutionizing the way we manage pipelines and distribution systems.

Introduction

Line stopping is a technique that allows professionals to halt the flow of liquids or gases in a pipeline temporarily. This method is particularly crucial in industries where downtime is costly and must be minimized.

The Mechanism of Line Stopping

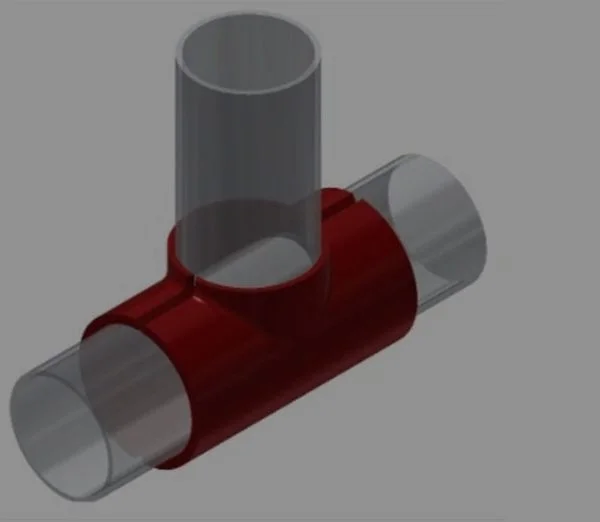

Understanding the basics of line stopping is essential for grasping its significance in various applications. The process involves strategically inserting a stopping device into a pipeline, creating a temporary barrier that halts the flow of the substance.

Applications of Line Stopping

Line stopping finds applications in diverse fields, from industrial pipelines carrying chemicals to municipal water and gas distribution systems. Its versatility makes it a go-to solution for various scenarios.

Advantages of Line Stopping

The benefits of line stopping extend beyond mere convenience. By minimizing downtime and offering a cost-efficient alternative to complete shutdowns, industries can maintain operational continuity.

Challenges and Considerations

However, it’s crucial to acknowledge the potential risks and challenges associated with line stopping. Implementing robust safety measures is non-negotiable to ensure the well-being of personnel and the integrity of the system.

Line Stopping Equipment and Technology

Modern innovations in line stopping technology have streamlined the process, introducing features that enhance precision and efficiency. Professionals now have access to cutting-edge equipment designed to make line stopping more accessible and reliable.

Case Studies

Real-world examples of successful line stopping implementations provide valuable insights into the practical application of this technique. Examining case studies allows industries to learn from past experiences and optimize their approach.

How to Perform Line Stopping

For those unfamiliar with the line stopping process, a step-by-step guide can be instrumental. From initial preparations to the final implementation, understanding each stage ensures a smooth and effective operation.

Future Trends in Line Stopping

As technology continues to advance, the future of line stopping holds exciting possibilities. Emerging technologies and industry developments promise even more efficient and sustainable solutions.

Environmental Impact

With a growing focus on sustainability, it’s essential to explore the environmental impact of line stopping. Adopting green practices and eco-friendly solutions contributes to a more responsible and conscientious industrial landscape.

Regulatory Compliance

Adhering to industry standards and ensuring safety and quality are paramount in line stopping. Regulatory compliance ensures that practices align with established norms, promoting a secure working environment.

Training and Certification

Professionals involved in line stopping should undergo proper training and certification. Accredited programs equip individuals with the necessary skills and knowledge to perform line stopping safely and effectively.

Common Misconceptions About Line Stopping

Addressing myths and clarifying facts surrounding line stopping is crucial for dispelling misinformation. A clear understanding of the process promotes informed decision-making in industrial settings.

Interview with an Industry Expert

To gain deeper insights into line stopping, we interviewed an industry expert. Their perspectives and experiences shed light on the nuances and potential challenges associated with this essential technique.

Conclusion

In conclusion, line stopping emerges as a vital tool in the arsenal of industries reliant on uninterrupted processes. The ability to make necessary repairs or modifications without extensive downtime is a game-changer. As technology continues to evolve, line stopping is poised to become even more efficient, contributing to the seamless functioning of industrial systems.

FAQs

- Is line stopping suitable for all types of pipelines?

- Line stopping is a versatile technique applicable to various pipelines, including those carrying chemicals, water, and gas.

- How long does a typical line stopping procedure take?

- The duration of a line stopping procedure varies depending on factors such as pipeline size and complexity but is generally efficient, minimizing downtime.

- Are there any environmental concerns associated with line stopping?

- Line stopping can be performed with minimal environmental impact, especially when using eco-friendly practices and materials.

- What safety measures should be in place during line stopping?

- Robust safety measures, including personnel training and compliance with industry standards, are essential for a secure line stopping operation.

- How can industries stay updated on the latest advancements in line stopping technology?

- Industries can stay informed by participating in industry events, following reputable publications, and engaging with experts in the field.