In the dynamic realm of metallurgy, where innovation shapes the materials that drive industries forward, Monel K-500 emerges as a beacon of excellence. In this blog, we embark on a journey through the manufacturing processes of Monel K-500 wires, exploring the intricate techniques and cutting-edge innovations that fabricate the future of this high-performance alloy.

Alloy Alchemy: Crafting Monel K-500 from the Perfect Blend

At the heart of Monel K-500 lies a meticulously crafted alloy. Delve into the art of alloy alchemy, where nickel and copper join forces with precise proportions of other elements, giving birth to an alloy with unparalleled strength, corrosion resistance, and durability.

Hot Working Marvels: Forging Strength in Monel K-500 Wires

Explore the hot working processes that infuse Monel K-500 wires with strength. From forging to heat treatments, witness the transformative journey at elevated temperatures, setting the foundation for the alloy’s robustness.

Cold Drawing Precision: Shaping Monel K-500 with Accuracy

In the cold drawing arena, precision takes centre stage. Uncover the techniques employed to shape Monel K-500 wires with exact dimensions, ensuring uniformity, surface finish, and the high-quality standards demanded by modern industries.

Extrusion Excellence: Transforming Monel K-500 Alloy into Wires

Step into the world of extrusion, where Monel K-500 alloy undergoes a metamorphosis into wires. Understand the machinery and processes that drive this transformation, delivering wires with exceptional mechanical properties and surface characteristics.

Quality Assurance Odyssey: Ensuring Excellence Every Step of the Way

Quality assurance is paramount in the manufacturing of Monel K-500 wires. Navigate through the rigorous testing protocols and quality control measures implemented at every stage, ensuring that each wire meets the highest standards of reliability and performance.

Machining Mastery: Cutting-Edge Technologies in Monel K-500 Fabrication

Explore the cutting-edge machining technologies that elevate the precision and efficiency of Monel K-500 wire fabrication. From advanced CNC machining to innovative shaping techniques, witness the marriage of technology and craftsmanship.

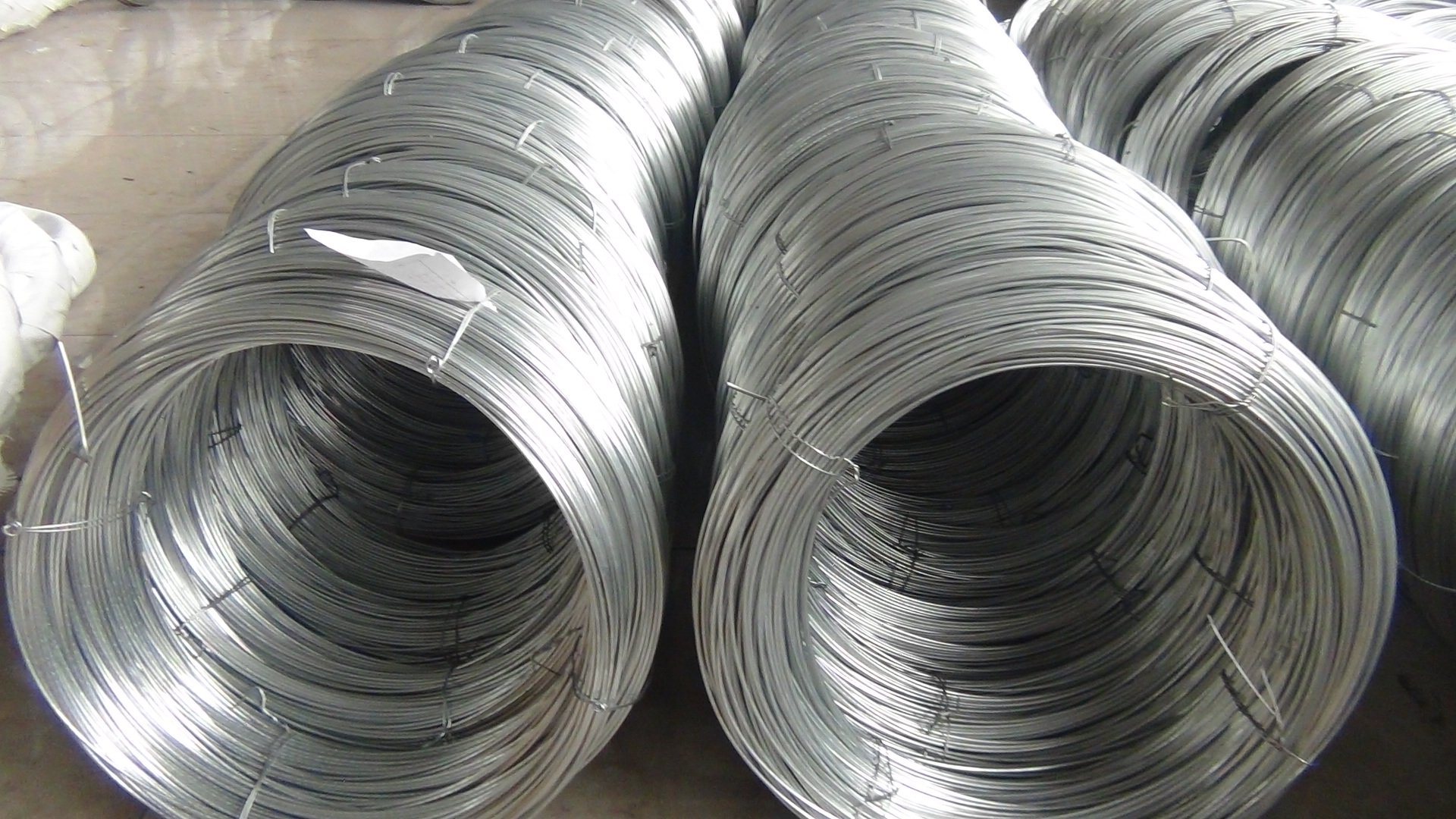

Wire Coiling Artistry: Creating Order from Monel K-500 Wires

The wire coiling process transforms individual wires into manageable spools, contributing to ease of use and transportation. Dive into the artistry of wire coiling, where precision and uniformity are paramount for various industrial applications.

Sustainable Manufacturing: Green Initiatives in Monel K-500 Wire Production

In pursuing a sustainable future, discover the eco-friendly practices integrated into manufacturing Monel K-500 wires. Explore initiatives aimed at reducing environmental impact and promoting responsible production.

Innovations in Wire Drawing: Shaping the Future of Monel K-500 Technology

Examine recent innovations in wire drawing techniques for Monel K-500, showcasing advancements that enhance efficiency, reduce waste, and push the boundaries of what is achievable in wire manufacturing.

Craftsmanship in Action: Skilled Hands, Superior Monel K-500 Wires

Celebrate the role of skilled artisans in the manufacturing process of Monel K-500 wires. Acknowledge the expertise and experience that contribute to the creation of wires that embody the pinnacle of metallurgical craftsmanship.

Conclusion:

As we unravel the manufacturing processes of Monel K-500 wires, it becomes evident that innovation and craftsmanship are at the core of fabricating the future. From alloy inception to the final product, each step is a testament to the dedication to excellence that defines Monel K-500. In materials engineering, Monel K-500 wires stand as a beacon, showcasing that the future is not just fabricated—it’s meticulously crafted for strength, resilience, and performance.