In the realm of high-temperature applications, one indispensable tool reigns supreme – the ceramic crucible. These unassuming vessels play a pivotal role in industries as diverse as metallurgy, chemistry, and materials science. Join us on a journey as we delve into the world of ceramic crucibles and discover the science, technology, and versatility that make them indispensable.

The Foundation: What Is a Ceramic Crucible?

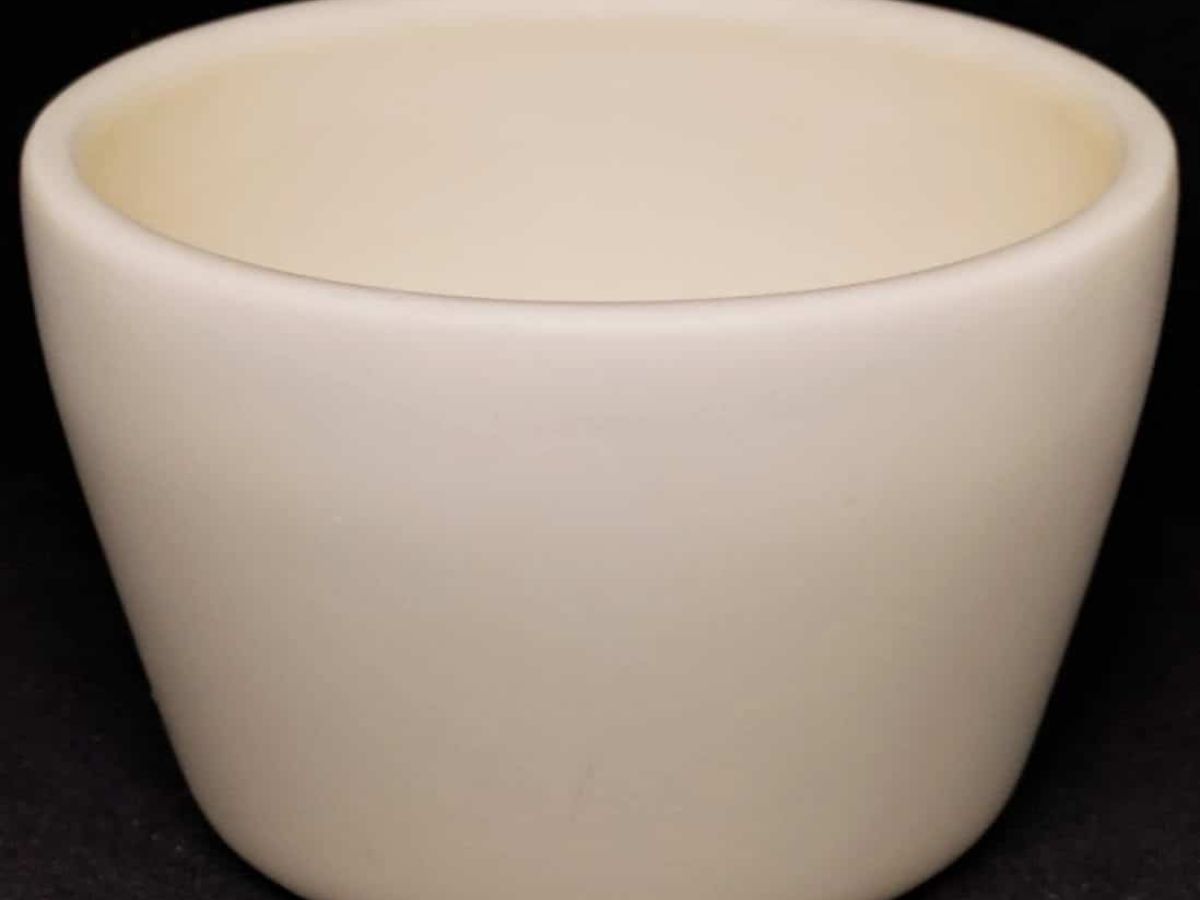

At its core, a ceramic crucible is a high-temperature container engineered to withstand extreme heat without succumbing to its fiery embrace. Crafted from a variety of ceramic materials, these crucibles come in various shapes and sizes, each tailored to specific applications. The choice of material depends on the intended use, with alumina, zirconia, and silica being popular choices due to their exceptional heat resistance.

The Alchemy of Ceramic Crucibles

The Melting Pot of Metallurgy

In the metallurgical domain, ceramic crucibles take center stage during the melting and casting of metals. Their remarkable ability to withstand temperatures exceeding 1,600°C makes them an ideal choice for the smelting of metals like gold, silver, and platinum. The ceramic crucible’s inert nature ensures that it won’t contaminate the precious molten metals, guaranteeing the purity and quality of the final product.

Chemistry’s Trusted Companion

In the world of chemistry, precision is paramount. Ceramic crucibles are instrumental in conducting experiments involving high-temperature reactions and the analysis of volatile substances. Their non-reactive properties ensure that the chemical composition remains unaltered during experiments, paving the way for accurate and reliable results.

The Art of Choosing the Right Crucible

Selecting the appropriate ceramic crucible for your application is akin to choosing the right tool for the job. Factors such as temperature requirements, chemical compatibility, and crucible size must be carefully considered.

Temperature Tolerance

Different applications demand different levels of heat resistance. For instance, experiments involving the fusion of platinum necessitate a crucible with an exceptionally high melting point, while ceramic crucibles designed for glass production may require slightly lower temperature resistance.

Chemical Compatibility

Understanding the chemicals and substances that will come into contact with the crucible is crucial. Some ceramic materials may react with specific compounds, potentially compromising the integrity of the crucible and the experiment’s accuracy.

Size Matters

The crucible’s size should align with the intended use. For small-scale experiments, a miniature crucible may suffice, but large-scale industrial processes demand substantial vessels to accommodate the volume of materials.

Innovations in Ceramic Crucibles

Reinventing Precision with Advanced Ceramics

Recent advancements in material science have given birth to advanced ceramic crucibles that push the boundaries of what was once thought possible. These state-of-the-art crucibles exhibit even greater temperature resistance and durability, opening up new avenues for research and industry.

The Final Word

Ceramic crucibles are the unsung heroes of high-temperature applications. From metallurgy to chemistry, their unwavering reliability and precision have revolutionized industries. To unlock the full potential of these incredible vessels, understanding their intricacies and choosing the right crucible for the task at hand is paramount. With the right ceramic crucible in your arsenal, you’ll be equipped to tackle the most challenging high-temperature endeavors with confidence and precision.